|

|

How to Operate the Solid

Target System

Overview

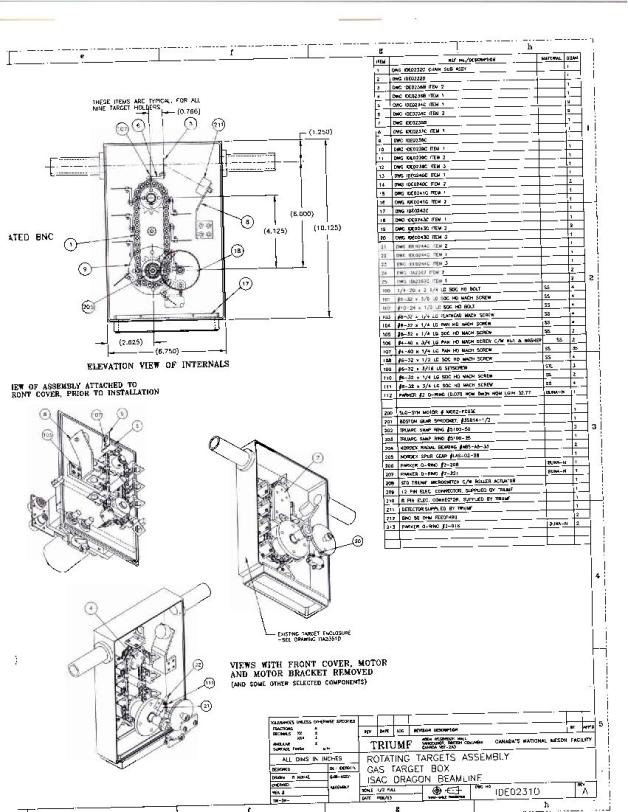

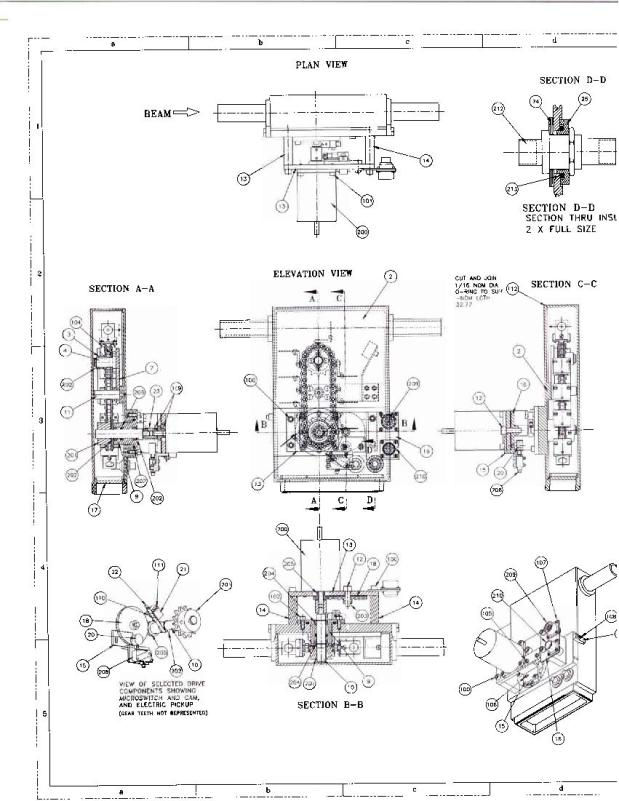

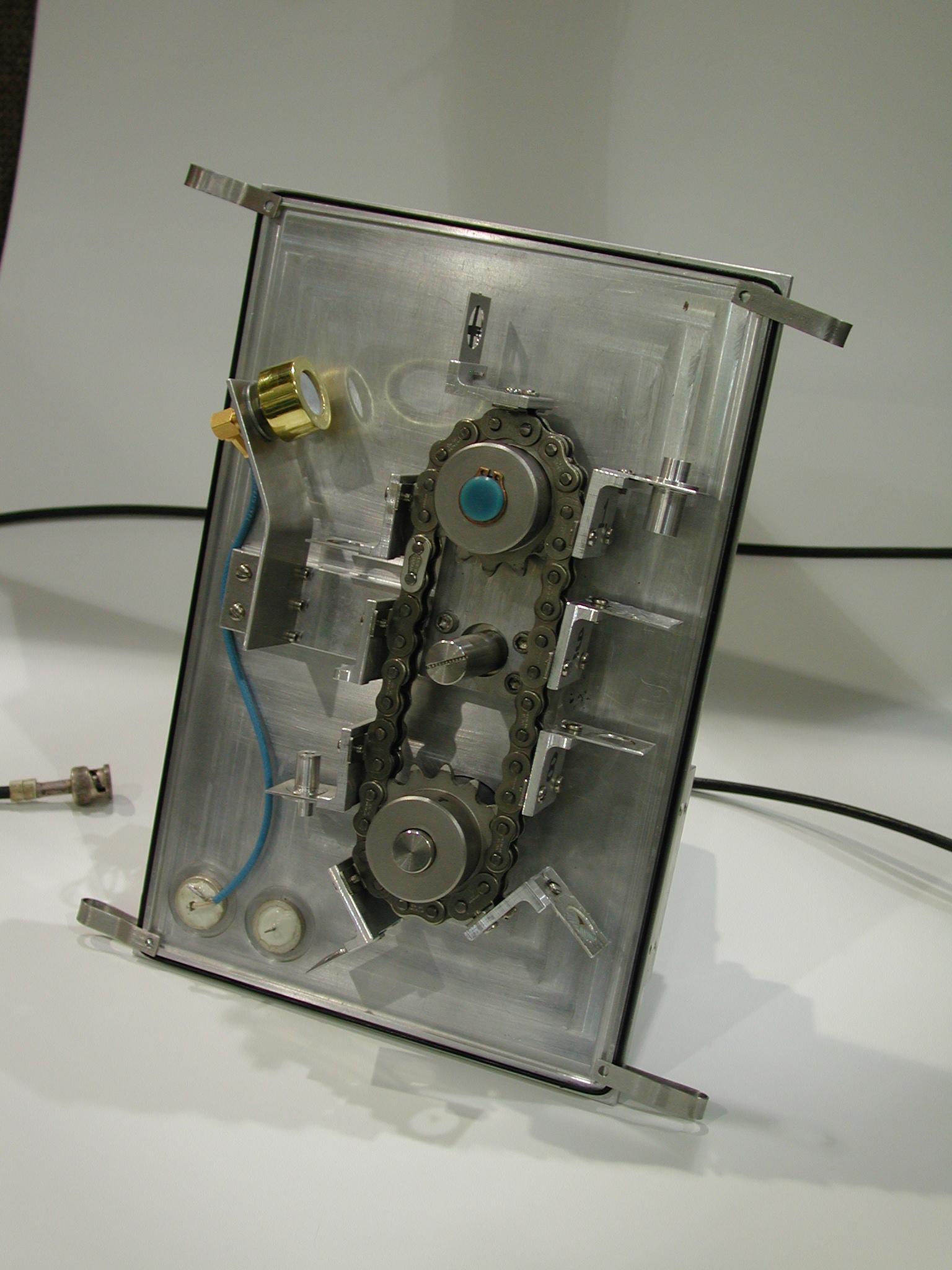

The solid target mounting system allows insertion of any one of 9 solid targets

into the beam at the centre of the DRAGON target box. It is designed to permit

operation of the BGO array in the same way as with the DRAGON gas target.

Accordingly, the target drive mechanism is mounted on a plate which can form one

side of the target box, in exactly the same way as the side-plate which supports

the gas cell.

The principal features of the system are:

- stepping motor controllable through EPICS

- coupler and feed-through from the motor to a drive sprocket inside vacuum

- a second gear and chain containing 9 target mounting bases

- cam-actuated microswitch for position calibration

- a Si detector for monitoring beam intensity and target integrity

- electrically insulated target drive for external current readout or application

of bias voltage

- an "ash-tray" to catch debris from broken targets before it drops into

the Roots blowers

If it has been a long time since the solid target ladder was used,

some key pieces may have been mislaid. Before starting the procedure

outlined below, the following should be confirmed:

EPICS control via the SOLTAR button on DRAGON page Optics(1) has been

enabled; target frames of the correct size are available; the rectangular

"ash tray" piece, or equivalent, to block the opening between the target

box and the pumping Manifold is available.

It also is convenient to have clips to hold the target side plate in place prior

to pump-down.

Mounting targets on the drive

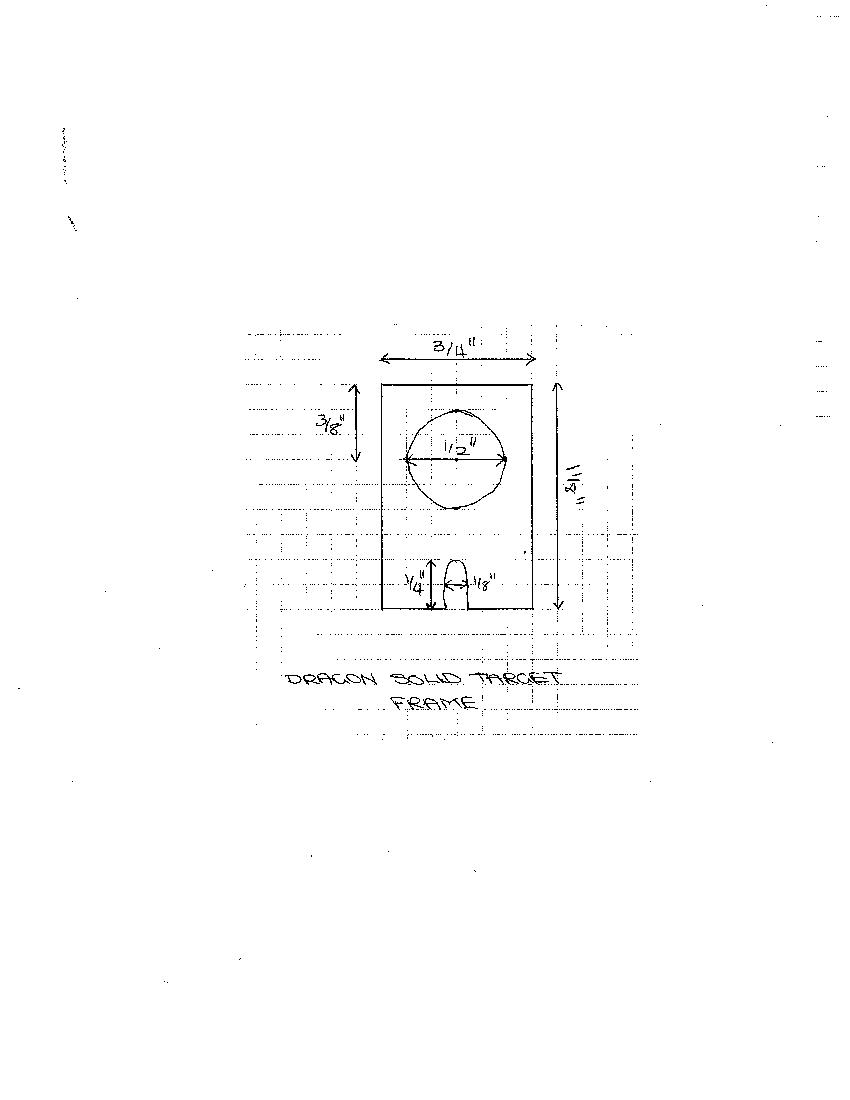

Targets should be mounted on frames which fit into the base and which have

the correct base-to-beam distance. They should not be longer (taller)

than the standard frame, to avoid hitting the Si monitor counter or the

inside of the vacuum box. See the AlisonCAD figure below, for key

dimensions.

Mounting the drive system on the

DRAGON target

box To replace the gas target cell with the solid target drive:

- If an Elastic Monitor detector is in use, check that its bias voltage

is off.

- Vent the target system to 1 atmosphere (see Vaccum instructions)

- Crank back the BGO array to give clear access to the target box

- Remove the bellows connection to the gas target side-plate and

blank the bellows off with the brass blank-off (which should have

been stored in the Target Parts box). Lay the loose end of the

bellows on the support for the motor of the adjustable valve.

- Disconnect gauge CMGC and lay it between turbo pumps TP2 and TP4.

Re-clamp the o-ring and T-ring to the gas target capilliary tube

so they don't get lost.

- Remove the gas target side plate. Put its o-ring on the solid

target side plate. Remove the in-board pumping tubes ("A" and

"B" or "C") and put them in the Target Parts box.

- If the solid targets are fragile, vent the Inlet Buffer Tank to 1

atmosphere: close VNT1 and open BYP1, FILLV.

- Cover the hole at the bottom of the target vacuum box with the

"ash-tray". Be sure to orient it as shown by the arrow, to allow

proper seating of the side plate on the vacuum box.

- Rotate the stepping motor by hand to position the most fragile

targets at the bottom positions.

- Use clips (should be stored in the Parts box) to hold the o-ring

at the top corners of the side plate. Two people, each one holding

the o-ring in place at one of the bottom corners, slide the plate

in place, capturing the o-ring at the bottom. Tilt the top of the

plate in place, remove the clips and secure the plate in place.

Use 2 C-clamps on opposite sides of the plate at the edge,

tightened gently (walls are thin!). After successfull pumpdown,

the C-clamps should be replaced by compact clamps, attached to

strings, at a height that will miss the BGO array tables..

- Pump down. If the targets are fragile, it is important to have

BYP1 and FILLV open so that the capacitive manometer CMBT in the Inlet

Buffer Tank can be used to monitor the rate of pumpdown.

- Close the manual "Varian" valve located between GOT1V and GOT2V,

located on the upstream side, north-east corner of the gas-target

platform. It is labelled MV-sloR.

- With roughing pump RP1 on, valve RV5 open and RV2 closed, open

valves GOT1V and GOT2V. While one person watches the pressure at

CMBT, a second person should slowly open the manual valve until a

pumpdown rate of about 1 Torr/second is achieved.

- Adjust the manual valve from time to time to maintain the pumping

rate. Below 100 Torr, pressure may be read on CMTRIN as well. When

the pressure falls below 10 Torr, RV2 may be opened and the Roots

Blowers (RB1B, RB1A, RB2A, RB1, RB2) turned on.

- Pressure at CMTRIN should quickly drop to 0.5-0.8 Torr. If it

doesn't, there may be a problem with the seating of the side plate on

the target box: check that there is not a gap at any point where they

meet.

- Start turbo pumps and when they are up to speed (icons change

from dark green to light green) turn on ion gauges IGU3 and IGD4.

- Connect the motor control cables. They should pass above

the BGO carriage, to allow proper closure of

the BGO array. Connect the Si detector pre-amp cable to the

right-most BNC connector on the side plate and provide strain

relief to support the weight of the pre-amp+heavy cables.

Connect the current readout to the bias-box/integrator line.

- Check the motor drive. Do "Calibrate" and then try at least one

other target position. When vacuum is good, turn on IGU3, IGD4

open valve IV11 and check position of a small-aperture target

by viewing with the CCD camera.

- With one person cranking/watching and a second person watching for

collision, slowly crank the BGO array carriage in until it

reaches the stop-bars.

Target selection via EPICS

Select from DRAGON's EPICS menu Optics|Optics(1)|SOLTAR.

(It's at the lower right of Optics(1).) The CALIB button will drive

the target chain to the Target I position. Other targets are indicated

by the Roman numeral immediately to the right of the word "Target".

Click on the appropriate button and you should see the destination number

(black) change immediately, while the numbers in blue indicate progress

towards the destination.

Before mounting the solid target system on the target box, it is important

that a good record be made of which target is mounted in which location.

Due to a glitch, if the DRAGON IOC

is rebooted, some of the numbers in the stepping motor control get set

wrong. The symptom will be that the chain goes around about two complete

turns when the requested change is only one target. To get the correct

operation, select on the DRAGON EPICS menu Diagnostics|Motor diagnostics|

Solid target. Under CALIBRATION the value should be 133.81 mm/rev and

12.70 mm/sec; under Step size -800 for min value and 800 for max val.

(See /home/dragon/soltarnumbers.ps for a display of correct settings.)

Viewing targets with the CCD camera

The "available light" from ion gauges is enough to provide information

about the selected target, provided there are no intervening obstructions

(gate valves or Faraday cups). The best back-lighting comes from IGU3

when gate valve HEBT2:IV8 is closed, but when IV8 is open (and HEBT2:FC4 is

out!) useful light comes from HEBT2:IG2 in 5-10 second exposure times.

Some observables:

- Position of collimator hole, for beam tuning. (Due to the offset

between the plane of the target frame and the point of attachment to the

chain, the proper in-beam position is not the highest point attained

by a target when moving between target positions.)

- Integrity of thin C targets. The intensity of light scattered off IV8

and passing through a thin (brownish, but "transparent") C target was

observed to be only 20% of the transmission through an empty target frame.

Calibration of light attenuation when the target is known to be intact

should allow rapid checks of target whole-someness later.

- Scintillation induced by beam. It has been found that at

multi-nanoAmp intensities an ordinary microscope glass slide will give off

enough light to be visible on the CCD; a slide fragment with a thin carbon

layer to prevent charge buildup has been glued to one of the target

frames. At 50 particle nA of 12C beam, a 40 ug/cm^2 C target gets hot

enough at the centre to make a visible incandescent glow. Light has been

observed from thin mylar films, but only temporarily as they melt!

- "Cross-hair" alignment target. A crude alignment target was made by

stretching two thin strips of black tape across a blank target frame. The

strips are off centre, such that the intersection of their two edges

marks the centre of the target frame. Two indentations, one on the edge

of each

strip, indicate which pair of strip edges define the centre-lines.

Venting the solid target system to 1 atmosphere

If the targets are fragile, slow venting is required and the usual

venting procedure should be replaced by the following:

- Close isolation valves IV8 and IV11. Turn off the ion gauges

IGD4 and IGU3. Turn off the turbo pumps and the Roots blowers.

Close RV2. From the pumpdown stage, the Inlet Buffer Tank should be

at low pressure (read on CMBT). (If it is not, pump it out via RV4

and RV5; open FILLV, close RV4 and open BYP1.)

- Call a gas target Expert and have them bypass the interlock on the vent valve VNT1.

Ask them to explain the possible consequences of a bypassed interlock.

- Wait 15 minutes for (partial?) turbo spin-down

- Close the (unknown to EPICS!) manual valve in series with VNT1.

It is under the gas-target platform, identified by a pink ribbon.

Access to it is gained by removing the mobile stairs which give access

to the south-west side of the platform and reaching across a box fan

towards the beamline, at the downstream edge of the platform.

- Open VNT1. Slowly open the manual valve (of order 1/4 turn)

until pressure rise is noted on CMTRIN and CM1. If the pressure rises

above 1 Torr, close VNT1. If a rattling sound is heard at the target,

close VNT1.

- As the turbos spin down, you may see the pressure at CMTRIN

and/or CM1 fall, even though VNT1 is still open. This signals that

the turbo spin-down has reached a point where they are no longer

compressing gas into the volumes sensed by CMTRIN/CM1.

- Supply dry nitrogen gas to the venting line: at the south side

of magnet MD2 is a cylinder of compressed dry nitrogen. Ensure that

the hand valves "LN2 dewar pressure" and "Separator vent" are

closed. Open the valve on top of the gas cylinder; the right-hand

gauge should indicate 100's of PSI pressure. If the left-hand gauge

indicates a reduced pressure greater than 0, turn the reduction-valve

knob counter-clockwise several turns. Open "Separator vent" hand

valve; pressure indication on the left-hand gauge should drop quickly;

if it does not, turn the knob further counter-clockwise until the

reading does drop.

- Turn the pressure-reduction knob clockwise until a reading near 0

is obtained.

- Open VNT1 and monitor the rate of pressure rise at CMBT. Adjust

the manual valve in series with VNT1 to achieve pressure increase of

about 1 Torr/second.

- When CMBT gets close to 750 Torr, pressure rise may stall. Try

adjusting the reduction valve at the gas cylinder to be slightly above

0.

- When CMBT reaches 760 Torr. close VNT1. Close the valve on top

of the N2 gas cylinder, turn the reduction valve ccw and close

"Separator vent" valve. This is important: otherwise a whole cylinder

of gas will bleed away if you forget to do this.

- Pull back the BGO arrays

to give access to the target side-plate. Disconnect the motor drive

cables. Slip a C-clamp so that it sits atop the target vacuum box,

adjusted loosely so that it can prevent the plate from falling away

when the special clamps near the bottom of the plate are loosened.

- Gently break the seal between side plate and the rest of the box.

Carry the plate to a convenient working area (table), avoiding fans

and other sources of strong air currents.

Dave Hutcheon

8 August, 2005

27 March 2019

|